Hydraulic testing machine with mobile crossheads.

Test capacity up to 2000 kN, joined the versatility of mobile cross through hydraulic cylinders and blocks, to adapt to multitude of sizes of specimen.

Its compact design, makes installation eassier in places with low ceilings. Precision and accuracy measurement of UMIB series, fits any level of demand in most market applications, for industry as well as research laboratories.

UMIB series is characterized by being a material testing machine with high precision and accuracy,this is also joined to the versatility when tests on specimens of different dimensions.

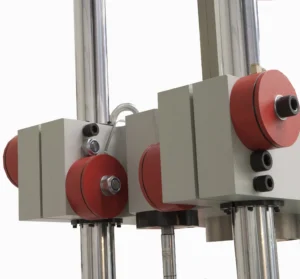

The two machine crossheads are moved by the hydraulic jacks situated on the sides, This task is performed automatically from the control pc of the testing machine, where we indicate the height at which we want to place the crosshead and once placed in this position, will be firmly locked by hydraulic locks placed at the ends of the crossheads.

This is a complete and versatile solution of testing machine, that meets the highest standards of quality, adaptability and precision at testing loads up to 2000 kN.

The testing machines series UMIB of IBERTEST, have different grippingheads and other testing devices, which allow different types of tests:

All performed on different materials used in industry and research fields as:

In our metrology laboratory where we have profile projector, hardness testers, roughness, 3D Coordinate measuring machines, etc.. are verified all key components of IBERTEST testing machines.

Our testing machines not only ensure its quality through quality control of each component, the machine is verified in a global way and functionality, being calibrated by our official calibration and certification laboratory, accredited by ENAC (ILAC member) which issues a calibration certificate valid internationally according to ISO 7500-1.

SERIE | UMIB-600 | UMIB-1000 |

Maximum load | 600 kN | 1000 kN |

According to ISO 7500 |

Class 0,5 | |

Load measurement |

Universal strain-gage load cell (tension-compression). | |

Load cell repeatibility |

Better or equal to ± 0.05 % | |

Measuring Range |

1 % to 100 % of the load cell nominal capacity (autoescale) | |

Strength Resolution |

5 dígits with floating coma | |

Vertical free clearance, with load |

Adjustable from 0 a 1000 mm | |

Number of columns |

4 columns. | |

Free gap between columns | 520 x 250 mm | 710 x 405 mm |

Mobile Crosshead |

Automatic movement by means of lateral hydraulic synchronous jacks. | |

Displacement measurement |

Encoder. Optional piston internal LVDT. | |

Power supply |

Three-phase 380 V plus neutral and earth, 50/60 Hz (to specify) | |

Total power | 3 kW | 4 kW |

Emergency stop |

”Mushroom“ type, placed on the testing frame and working table | |

Dimensions: Testing frame (mm) | 1020 x 650 x 2450 (h) | 1200 x 650 x 2600 (h) |

Approx Weight (without gripping heads) | 2100 kg | 3500 kg |

Dimensions / working table weight |

1200 x 800 x 900 mm (width x depth x height)/ 40 kg aprox. | |

Foundation |

Special foundation must be performed to allow piston hosting and correct leveling. | |