Available up to 3000 kN capacity.

Double test space is ideal for users that change in a short space of time tensile test and compression test, bending test, etc. A test zone is set up to the tensile test and the second test area is configured for compression or flexure test, eliminating changing times test accessory.

Compact design test high capacities without excessive height in the laboratory.

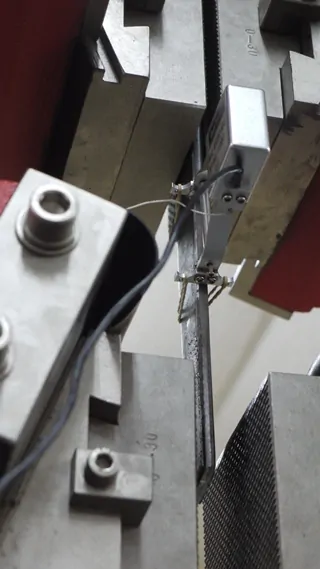

Hydraulic gripping heads embedded in intermediate crossbar for remote management. Remote controlled opening and closing of jaws and positioning of intermediate crossbar

Including bending and compression devices within the standard supply.

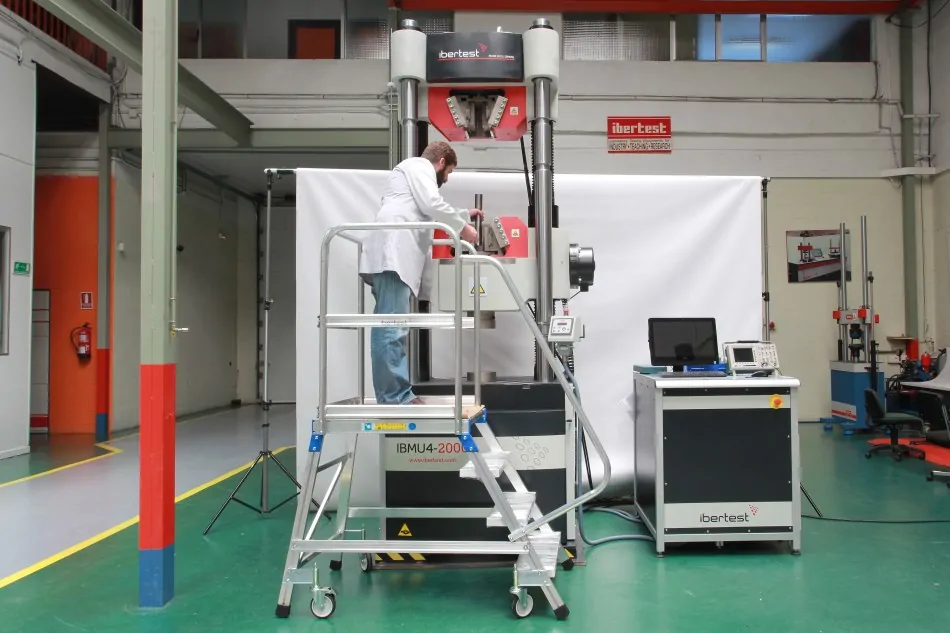

IBMU4 series is characterized by a material testing machine with hydraulic drive, which provides a high productivity to users performing several types of materials testing in a short period of time.

Providing two test areas on the same machine, we can get ready for 2 different types of test, first a tensile test in integrated hydraulic gripping heads and secondly, a compression test, bending, etc.

The capacity reached by this series of machines is 2000 kN, which makes them an ideal choice for testing on corrugated steel structures, thick metal cylinders, chains, etc.

Testing machines IBMU4 series of Ibertest, have different testing devices which covers a large number of different tests to be performed and different materials such as:

Some of the test for this machines series are prepared for testing:

The maximum liability elements of IBERTEST testing machines are subjected to a thorough evaluation by our metrology laboratory where we have equipment calibrated and traceable as profile projector, hardness testers, roughness, coordinate measuring machine, calipers, thermometers, metrological reference tables, etc.

The IBERTEST testing machines not only ensure its quality through quality control of its components, but rather are checked globally and functionally, using a calibration by our calibration laboratory and official certification, accredited by ENAC (ILAC member) which issues a calibration certificate is valid internationally, according to standard ISO 7500-1 for calibration of test machines.

MODEL |

|

|

|

|

|

Maximum load | 600 kN | 1000 kN | 1500 kN | 2000 kN | 3000 kN |

Class according to ISO 7500-1 | Class 0.5 | ||||

Load measurement | Strain-gage load cell | ||||

Measurement range | From 2% to 100% of the load cell nominal capacity | ||||

Load resolution | 5 digits with floating point | ||||

Load cell repeatability | Better or equal to ± 0.05 % | ||||

Columns nº (diameter) | 4 (ø 100 mm) | 4 (ø 110 mm) | 4 (ø 125 mm) | ||

Screw drivers nº (diameter) | 2 (ø 120 mm) | 2 (ø 140 mm) | |||

Piston stroke | 250 mm | ||||

Maximum loading speed | 80 mm/min | 50 mm/min | |||

Piston displacement speed | 160 mm/min | 100 mm/min | |||

Crosshead elevation speed | 350 mm/min | 200 mm/min | |||

Free distance (between columns) | 540 mm | 565 mm | 760 mm | 870 mm | |

Max.distance between tensile gripping heads (piston stroke included) | 780 mm | 1000 mm | 1450 mm | ||

Max. distance between compresion plates | 780 mm | 850 mm | 1250 mm | ||

Displacement resolution | 0,001 mm | ||||

Testing frame dimensions:(width x depth x height) mm | 910 x 790 x 2640 | 1420 x 1150 x 3800 | 1500 x 1150 x 3860 | ||

Testing frame approx. weight | 2900 kg | 10.120 kg | 11.000 kg | ||

Hydraulic workframe dimensions (width x depth x height) in mm | 910 x 980 x 1100 | ||||

Approx weight of the hydraulic workframe | 325 kg | ||||

Power supply | Three-phase 380 V plus neutral and earth, 50/60 Hz (to specify) | ||||