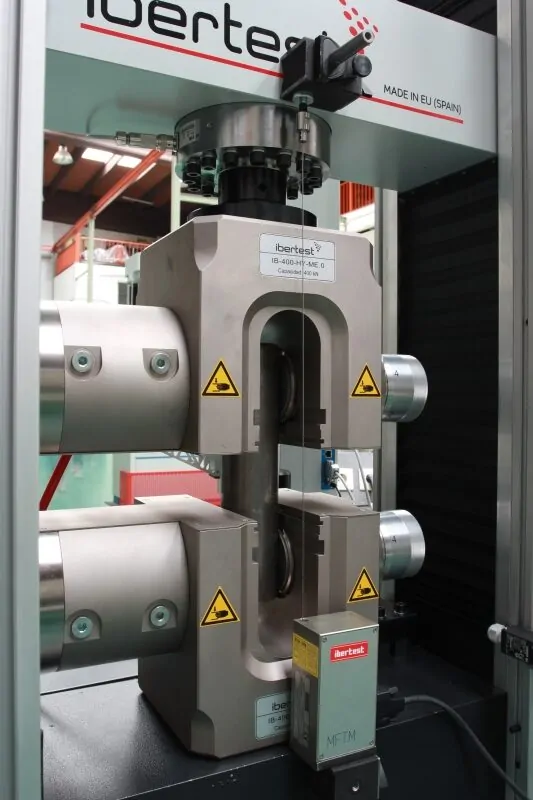

Customized and flexible design, single testing space or double testing space. Material testing machine developed to meet the highest standards in materials testing according to international test standards: ISO 6892 tensile test, IS 1608, EN 10002-1, ASTM D695 compression test, bending test ASTM E290, test according to NADCAP.

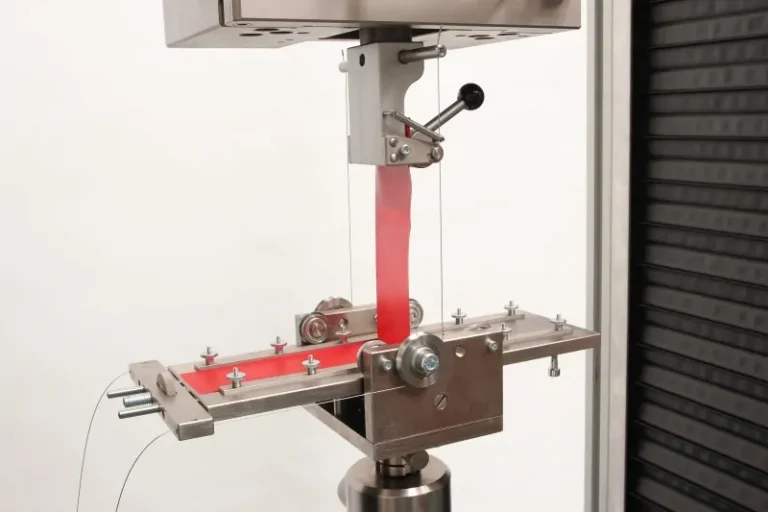

Maximum precision determination of the key parameters in multiple materials testing, such as the yield strength, 0.2% upper limit and lower creep rupture load, ultimate elongation, etc. Automatic calculation of anisotropy and sourness by combining axial and transverse strain gauges extensometers.

The available settings for EUROTEST series, of IBERTEST, are almost limitless. EUROTEST Electromechanical material testing machine can adapt to width, length, capacity (up to 1200kN), test standards, etc.. required.

The combination of a versatile framework with dozens of testing devices and interchangeable load cells, environmental chambers, furnaces, extensometry (manual and automatic) … give this a testing machine wide possibilities for all types of static and fatigue tests at low frequencies.

The material testing machine of EUROTEST series, combines the experience of over 40 years manufacturing material testing solutions . It arises from the application of the latest advances in technology for material testing, to the previous models of electromechanical material testing machine , ELECTROTEST and ELIB series.

More information

The maximum liability elements of IBERTEST material testing machine are subjected to a thorough evaluation by our metrology laboratory where we have equipment calibrated and traceable as profile projector, hardness testers, roughness, coordinate measuring machine, calipers, thermometers, metrological reference tables, etc.

All our machines go through a final and definitive verification of performance and functionality , being subjected to a calibration process by our official laboratory of calibration, accredited by ENAC ( ILAC member ) .

These electromechanical testing machines are particularly suitable for tensile testing according to ISO 6892 , IS 1608, EN 10002 – 1, ASTM D695 Compression test , bending test, ASTM E290 , tests according NADCAP GE- S400 , CREEP ASTM E 139 , ASTM E190 test welds , shear test , test materials at high temperature EN1002 -5, ASTM E 1012, fatigue tests for constant amplitude BS EN ISO 7270, fatigue testing at low frequency NFA 03403 , tensile and compression tests on ceramic matrix composites.

Application of any specimen type : standardized specimens with threaded or machined head , flat , welded metal joints mechanical and adhesive bonds among others.

Wide variety of materials can be tested in the testing machine EUROTEST: steel, titanium , aluminum, wood , composites, plastics, elastomers , rubbers , biomaterials, cement, medical materials, prosthetic teeth.

EUROTEST 50 & 100 | EUROTEST 200 | EUROTEST 300 | EUROTEST 400 | EUROTEST 500 | EUROTEST 600 | |

Class ISO 7500-1 | 0,5 From 0,5% to 100% FS | |||||

Maximum load | 50 kN 100 kN | 200 kN | 250 kN 300 kN | 400 kN | 500 kN | 600 kN |

Load measurement | Universal strain-gage load cell (tension-compression) | |||||

Force resolution | 0,0001 kN | |||||

Load cell Repeatibility | 0,025% | |||||

Horizontal clearance | 500 mm | 650 mm | 720 mm | |||

Vertical clearance, distance between standard gripping heads

| Ajustable between 0 and 1300 mm | Ajustable between 0 and 1400 mm | ||||

Displacement speed | From 0,001 to 1000,00 mm/min (other speeds on demand) | From 0,001 to 500,00 mm/min | ||||

Displacement measurement | Encoder (digital pulse sensor) | |||||

Displacement resolution | 0,1 micron | |||||

| GENERAL CHARACTERISTICS | ||||||

Dimensions: Testing frame (mm) | 1020 x 650 x 2450mm (width x depth x height) | 1200 x 650 x 2900 mm | 1550 x 690 x 2900 mm (width x depth x height) | |||

Approx weight ( without gripping heads ) | 1000 kg | 1200 kg | 1400 kg | 2900 kg | ||

Power supply | 3x 380 V + N+ T, 50/60 Hz | |||||