Compact, ergonomic and modern design, keeping maximum performance, for material testing.

With the right combination of accessories can do the tensile test ISO 6892, ISO 1608, EN 10002-1and ASTM E23, ASTM D695 compression test, bending test ASTM E290, test according to NADCAP, test to rubbers and elastomers on ISO 37, ruber properties ASTM D413, ASTM D412.

High stiffness and optimal performance in a small design.

With touch PC all in one , directly attached to the test frame to maximize ergonomics and reduced working space .

IBERTEST as official calibration laboratory accredited by ENAC , calibrate whole our machines according to international standards for verification of performance and functionality.

This is done with highly qualified staff, specially trained for such tasks.

This series of electromechanical machines can perform many tests: tensile test according to ISO 6892 , EN 10002 – 1and ASTM E23, ASTM E290 bending test , tests according to NADCAP GE- S400 , CREEP ASTM E 139 , ASTM E190 test on welds , testing shear , material testing at high temperature EN1002 -5 compression test ASTM D695 , ASTM E 1012 , ISO 1608 , fatigue tests with constant amplitude BS EN ISO 7270, fatigue tests at low frequency NFA 03403 , ASTM D412 .

Test can be performed on specimens of different sizes and shapes of preparation: standardized specimens with threaded head or machined flat, welded metal joints mechanical , adhesive bonding , etc. .

All materials for their test specimen dimensions fit in the maximum capacity of the machine, can be tested in the testing machine TESTCOM: steel, elastomers, wood, rubber , aluminum , composites , titanium , plastics, biomaterials , cement , equipment medical prosthetic tooth .

MODEL |

TESTCOM-5 TESTCOM-5/E |

TESTCOM-10 TESTCOM-10/E |

TESTCOM-20 TESTCOM-20/E | TESTCOM-30 | TESTCOM-50 | TESTCOM-100 |

Class ISO 7500-1 |

0,5 From 1% to 100% FS | |||||

Maximum load |

5 kN |

10 kN |

20 kN |

30 kN |

50 kN |

100 kN |

Force measurement |

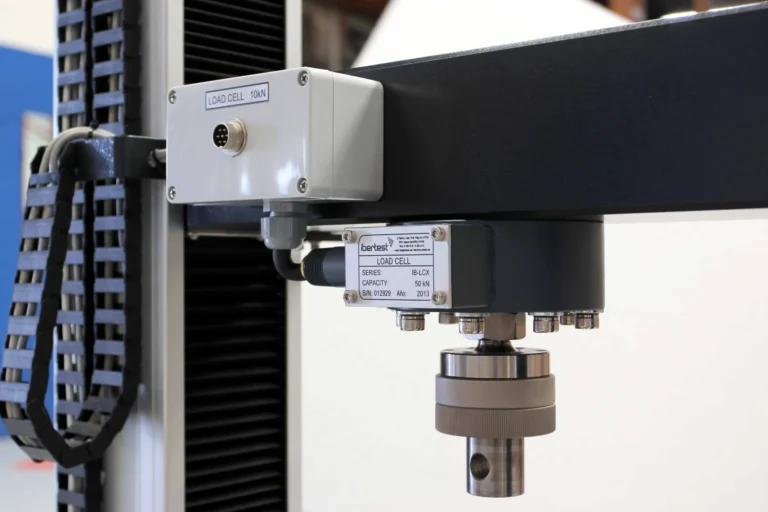

Universal (tensile-compresion) extensometric-bands load cell | |||||

Measuring Range |

From 1 % to 100 % of the load cell nominal capacity | |||||

50 – 5.000 N |

100 – 10.000 N |

200 – 20.000 N |

300 – 30.000 N |

500 – 50.000 N |

1.000 – 100.000 N | |

Force resolution |

0,1 N* | |||||

Columns |

2 grounded columns, chrome-plated steel | |||||

Ball screws |

2 high precision ball screw, with scrapers | |||||

Mobile crosshead |

Driven by the ball screws, guided by the 2 columns | |||||

Motor drive |

Synchronous servomotor (Brushless) with direct drive to screws by reducers | |||||

Gear transmission |

Motor-pulley and reducer-pulley connecting via HTD precision teeth belt | |||||

Movement speed range (mm/min) |

0,01 a 1000,00 |

0,5 a 500,00 | ||||

Load speed range (kN/s) |

Between 1% and 10% of maximum load capacity (others on demand) | |||||

0,0005 a 0,5 kN/s |

0,001 a 1 kN/s |

0,002 a 2 kN/s |

0,003 a 3 kN/s |

0,005 a 5 kN/s |

0,01 a 20 kN/s | |

Crosshead position measurement |

Encoder |

Resolver | ||||

Crosshead position resolution |

0,005 mm (5 microns), 1 micron is possible (on demand) |

0,001 mm (1 micra) | ||||

Power supply |

Single-phase 220V + earth, 50/60 Hz | |||||

Power consumption |

1400 W |

1000 W |

1500W | |||

Vertical free light with load cell, without fixtures |

700 mm |

1100 mm |

1300 mm | |||

Horizontal free distance |

425 mm |

450 mm | ||||

Dimensions (mm) |

720x510x1320*(h) |

1800x900x685 mm |

2015x900x705 mm | |||

Approx. weight without testing fixtures |

120 kg |

385 kg |

525 kg | |||

Safety |

Emergency push-button, located in the front of the machine | |||||