Versatile automated wetting and adhesion analysis of solids and liquids

The Expert version of the DSA30 Drop Shape Analyzer enables solids and liquids in wetting and coating processes to be analyzed comprehensively. The high degree of automation with easily programmable features provides for user-independent contact angle and surface tension results, which is ideal for the use in quality control. However, the DSA30E is also frequently used in R&D due to its versatility in controlling thermal conditions and its scientific tools for analyzing the solid/liquid contact.

The Expert version of the DSA30 Drop Shape Analyzer enables solids and liquids in wetting and coating processes to be analyzed comprehensively. The high degree of automation with easily programmable features provides for user-independent contact angle and surface tension results, which is ideal for the use in quality control. However, the DSA30E is also frequently used in R&D due to its versatility in controlling thermal conditions and its scientific tools for analyzing the solid/liquid contact.

The Expert version of the DSA30 Drop Shape Analyzer enables solids and liquids in wetting and coating processes to be analyzed comprehensively. The high degree of automation with easily programmable features provides for user-independent contact angle and surface tension results, which is ideal for the use in quality control. However, the DSA30E is also frequently used in R&D due to its versatility in controlling thermal conditions and its scientific tools for analyzing the solid/liquid contact.

Quality assurance of activation processes such as plasma treatment, flame treatment, or corona treatment

Analyzing wettability of plastics, glass, ceramics, wood, paper, or metal

Analyzing the effectiveness of hydrophobic coatings and other coatings

Analyzing coating liquids and adhesives and assessing their adhesion

Assessing long-term stability of coatings

Analyzing (super-) hydrophobic and self-cleaning surfaces

Analyzing homogeneity of cleanliness and wettability and measuring differences between coated/uncoated or treated/untreated areas

Wetting analysis at controlled temperature and/or humidity

Contact angle of a drop on a solid surface

Contact angles of two drops dosed in parallel

Automated position-dependent contact angle measurement and evaluation

Contact angle using a gas bubble beneath a solid surface in a liquid

Roll-off behavior and advancing/receding contact angle of a drop on a tilted surface

Surface free energy of a solid using contact angle data

Calculating adhesion-related scientific parameters for the interfacial contact

Surface or interfacial tension using the curvature of a drop or bubble at the tip of a needle

Surface tension using the curvature of a perfectly symmetrical drop on a circular sample pedestal

Calculating the polar and disperse part of the surface tension from contact angle and surface tension data

Carrying out a measurement up to 20 consecutive times and displaying the results together

Remote control of ADVANCE for integration in custom-designed, complex automations

Static contact angle

Advancing and receding contact angle

Contact angle using a bubble in a liquid

Roll-off angle

Surface free energy (SFE) according to the following models: Owens-Wendt-Rabel-Kaelble (OWRK), Fowkes, Extended Fowkes, Van Oss & Good (Acid-Base), Schultz, Wu, Zisman, Equation of State

Position-dependent contact angle and SFE

Surface tension of a liquid and interfacial tension between two liquids

Work of adhesion, solid/liquid interfacial tension, spreading coefficient

Temperature

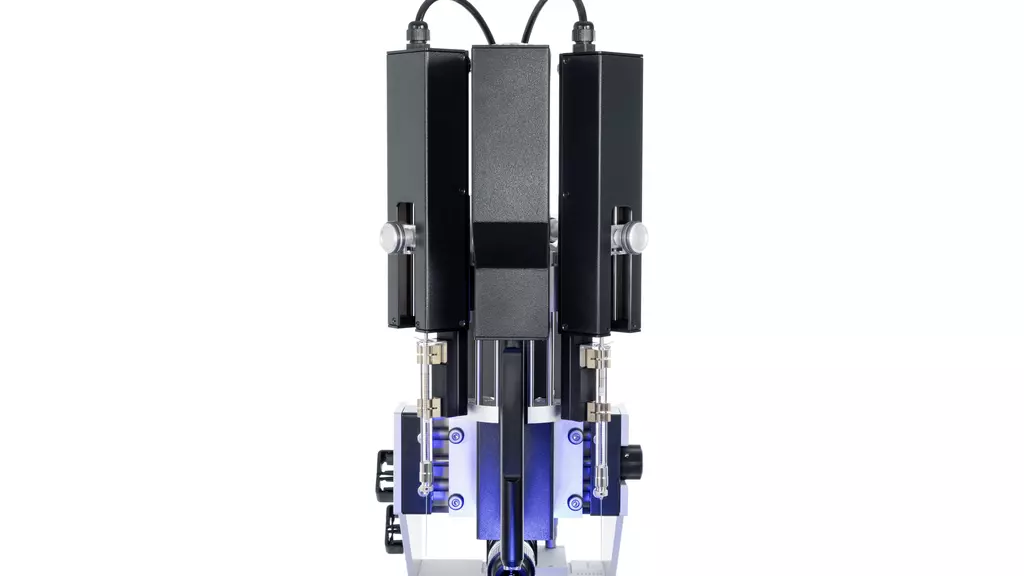

The DSA30E is equipped with the Dosing Hub for fast positioning and control of the dosing units. The instrument combines the automatic Liquid Needle for particularly fast and gentle dosing of two liquids with two software-controlled syringe dosing units for almost any liquid. This combination enables, for example, automatic, fast and reliable surface free energy measurements with four liquids. Alternatively, the DSA30E works together with a multi-dosing system with four syringes.

The DSA30E is fitted with three software-controlled axes. These move the sample accurately and quickly to all programmed measuring positions. This makes it possible to carry out complete, standardized analyses, which is ideal for quality control. Moreover, wetting can be analyzed dependent on the sample position to check for homogeneity or to assess differences between coated and uncoated areas, for example.

A high-resolution camera and a high-quality zoom lens ensure an accurate representation of the drop with optimal size. The high image quality that this achieves leads to a precisely measured contact angle or surface tension (SFT). Combined with the intelligent image evaluation algorithm of the ADVANCE software, drop shape analysis with the instrument provides exact results.

With the ADVANCE software’s easy-to-create automation programs you can design standard procedures for fully automated sample analyses in no time at all. Optional software tools for data analysis combine SFE and SFT data in order to assess the adhesion and other scientific parameters of the solid/liquid contact.