PARTICLE SIZE AND SHAPE ANALYZER

The CAMSIZER 3D particle analyzer combines all the advantages of dynamic image analysis (ISO 13322-2) in a completely redesigned measuring system, setting new standards in the characterization of bulk solids.

Unique 3D Analysis: Thanks to the extended field of view and long drop distance, each particle is analyzed up to 30 times and in different orientations, making the actual, three-dimensional particle morphology accessible for analysis. The evaluation of the “3D tracks” also provides much more meaningful shape analysis than ever before.

Proven 2-Camera System: The new ZOOM camera inside the CAMSIZER 3D (9 MPx) allows for the evaluation of fine particles with great accuracy. In combination with the BASIC camera (5 Mpx), this enables a wide measuring range from 20 µm to 30 mm. CAMSIZER 3D is the first choice for the analysis of dry, free-flowing bulk solids in both quality control and for research applications.

PARTICLE SIZE AND SHAPE ANALYZER CAMSIZER 3D

UNIQUE & PATENTED

The CAMSIZER 3D utilizes a funnel, vibrating feed chute, LED strobe backlighting, powerful high-speed cameras, and sophisticated software to perform the measurements.

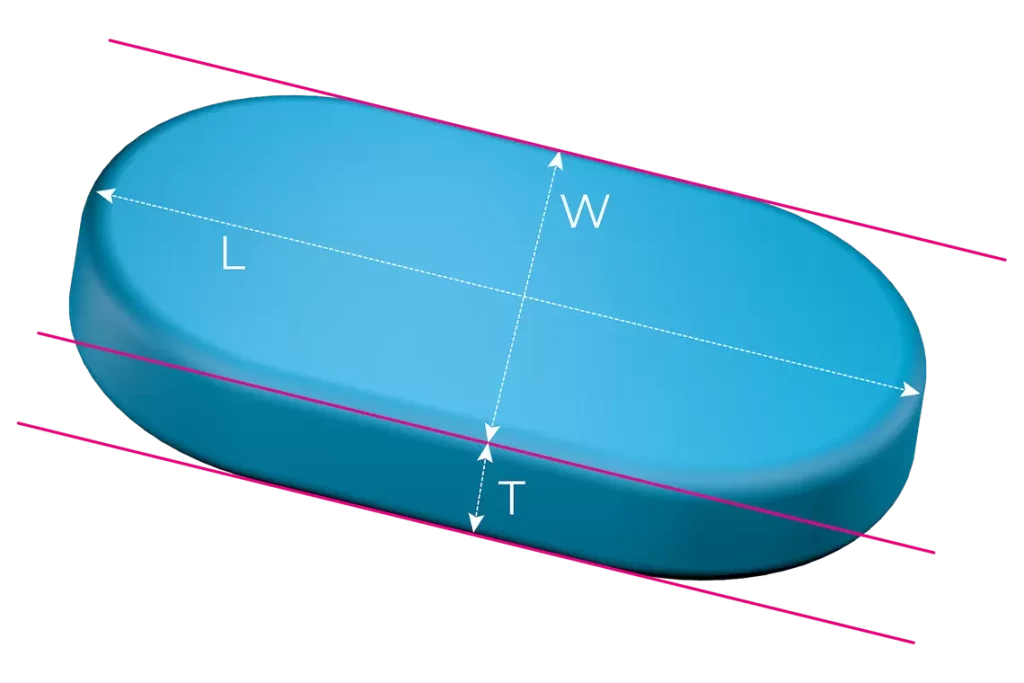

The particles travel down the vibrating feeder and fall into the sensing zone, creating a tumbling motion as they fall. The CAMSIZER software tracks each particle as it passes between light source and cameras, taking up to 250 images per second. As the particle is tracked, multiple images are recorded, measuring length, width, thickness, perimeter, area and various shape descriptors. The software automatically aligns the images for viewing, with up to 30 images per particle. This creates a “particle track”, a sequence of images of the same particle in different orientations. From this, distributions can be calculated, based on one or more size or shape parameters. Filters can be applied to isolate groups of particles of particular interest for more targeted analysis.

In the particle track, the software determines the width and the length of each particle projection:

3D BEATS 2D

In contrast, traditional 2D analysis captures only one image per particle in random orientation, even if the particle in measured multiple times at increased acquisition rate, there is no “mapping” of one image to another. Each individual image is treated as a new, independent measurement event. The true length, width, thickness, and shape is obscured by this. Rather, the “length” measured in 2D mode is a mixture between true 3D length and true 3D width; the “width” measured in 2D mode is a mixture between true 3D width and true 3D thickness. Only if the particles can be mechanically aligned, meaningful results are obtained in 2D mode. In the past, however, this was only feasible for some special particle shapes like cylinders.

Measurement in 2D Mode

Measurement in 3D Mode